For makers, crafters, and entrepreneurs, a laser engraver opens doors to countless creative and business opportunities. But with multiple technologies available — CO₂, diode, and fiber — it can be confusing to know which machine is the best fit.

This guide focuses on the practical differences between these three types of lasers, with insights into real-world use cases and how they impact small businesses, hobbyists, and side hustlers.

1. How the Three Laser Types Differ

CO₂ Laser

-

Emits 10,600 nm infrared wavelength.

-

Strong with organic materials (wood, acrylic, leather).

-

Typically larger, water-cooled, and more complex.

Diode Laser

-

Uses compact diodes (blue light ~450 nm).

-

Affordable, portable, and beginner-friendly.

-

Works with 350+ materials when paired with IR modules.

👉 Example: The Falcon A1 Pro 20W combines power and flexibility in one small unit.

Fiber Laser

-

Emits 1064 nm infrared via fiber optics.

-

Designed for metals and industrial plastics.

-

Expensive and usually overkill for hobby use.

2. Real-World Use Cases

-

CO₂ Laser Users:

-

Acrylic signage companies.

-

Small shops making décor at scale.

-

Schools or makerspaces with bigger budgets.

-

-

Diode Laser Users:

-

Etsy sellers offering personalized gifts (cutting boards, coasters).

-

Hobbyists engraving wood, leather, or coated metal.

-

Entrepreneurs testing business ideas with low startup costs.

-

-

Fiber Laser Users:

-

Industrial workshops marking tools, machine parts, or jewelry.

-

Professional engravers specializing in metals.

-

3. Cost and Business Investment

| Laser Type | Cost Range | Best Fit |

|---|---|---|

| CO₂ | $2,000–$6,000+ | Professional shops, heavy use |

| Diode | $400–$2,000 | Hobbyists, Etsy sellers, startups |

| Fiber | $6,000–$20,000+ | Industrial companies |

👉 If you’re starting a business from home, diode lasers are by far the most cost-effective.

4. Materials That Sell Well Online

-

Wood Products → Cutting boards, signs, ornaments. (Diode + CO₂)

-

Acrylic Décor → LED signs, wedding table numbers. (Best with CO₂)

-

Metal Jewelry → Rings, pendants, stainless plates. (Fiber or IR diode modules)

-

Leather Goods → Wallets, belts, keychains. (Diode or CO₂)

5. Safety and Workspace Considerations

-

CO₂ Lasers → Require more space and cooling systems.

-

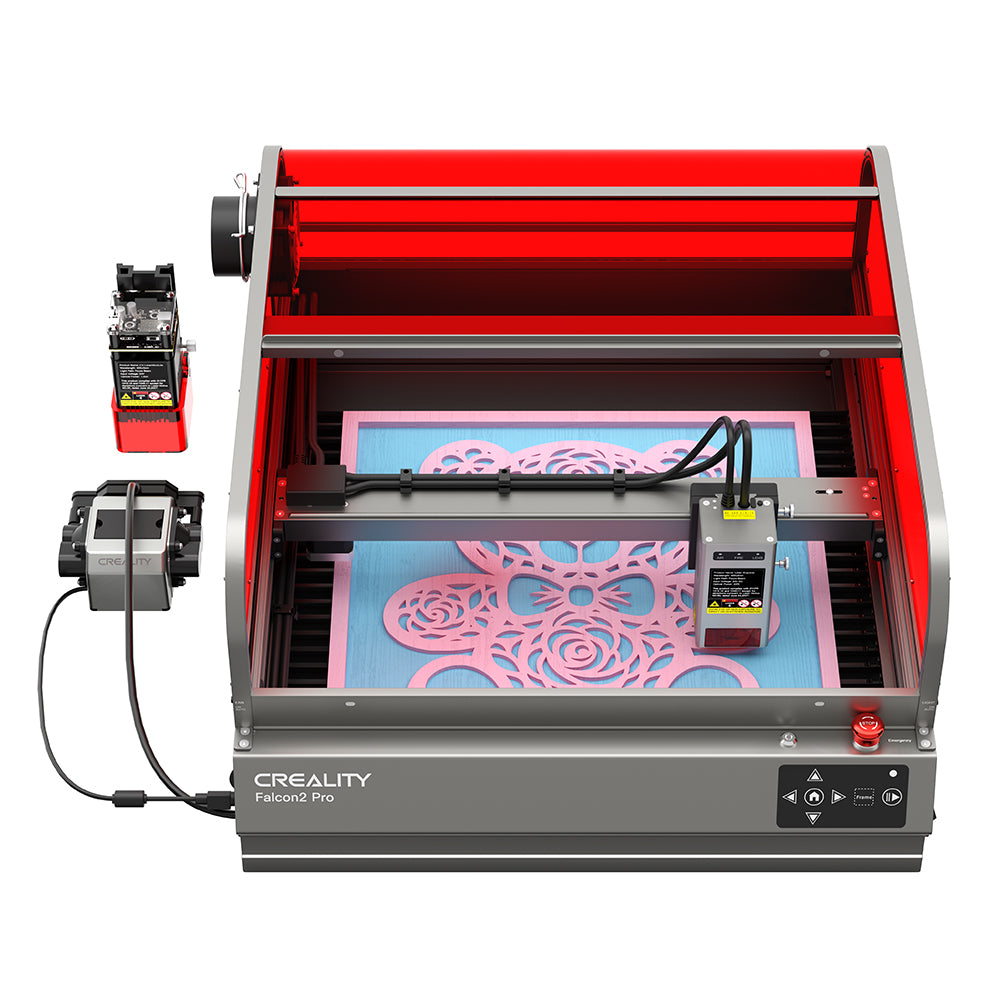

Diode Lasers → Compact and safer for home setups, especially enclosed models like the Falcon2 Pro 40W.

-

Fiber Lasers → Must be used in professional environments with proper shielding.

6. Which Laser Fits Your Goals?

-

Choose CO₂ if: You want to cut thick acrylic or wood and have the budget/space for a larger machine.

-

Choose Diode if: You’re starting a home-based business, side hustle, or Etsy shop and want versatility at a lower price.

-

Choose Fiber if: Your focus is industrial metal engraving.

👉 For most beginners and small business owners, a diode engraver like the Falcon A1 Pro 20W offers the best balance of price, safety, and creative potential.

Conclusion: Match the Machine to Your Vision

There’s no one-size-fits-all answer — the right laser depends on what you want to create and sell.

If you’re a maker or small business owner looking to balance affordability, material range, and safety, diode lasers are the best starting point.

👉 Explore the Creality Falcon collection — from the versatile Falcon A1 Pro 20W to the powerful Falcon2 Pro 40W.