Introduction: The Choice Makers Often Face

If you’re setting up a workshop or looking to expand your creative capabilities, one question often comes up: Should I invest in a laser engraver or a CNC router?

Both machines are designed to cut, shape, and customize materials, but the way they do it — and the results they produce — are very different. Choosing the right one isn’t about which is “better” overall, but which is better for your specific projects.

The Basics: How Each Technology Works

Laser Engraving

A laser engraver uses a focused beam of light to vaporize or burn material with extreme accuracy.

-

Strengths: Speed, precision, versatility across hundreds of materials.

-

Best for: Personalization, fine detail, thin cuts.

-

Examples: Jewelry engraving, acrylic signs, leather wallets.

CNC Routing

A CNC router uses a mechanical spindle with rotating bits to cut and carve.

-

Strengths: Depth, durability, handling thick materials.

-

Best for: Furniture, cabinetry, aluminum parts.

-

Examples: Wooden panels, carved reliefs, custom furniture parts.

Thinking About Your Projects

Before comparing specs, think about what you want to make:

-

Do you want to personalize products with logos, text, or images? → Laser engraver.

-

Do you want to build structural pieces like tables or mechanical prototypes? → CNC router.

-

Do you want to cut thin sheets quickly for signs, crafts, or decorations? → Laser engraver.

-

Do you need to carve deeply into wood or machine metal? → CNC router.

Workflow and Learning Curve

Laser Engraver Workflow

-

Import or design your file in software (LightBurn, Illustrator).

-

Position material and adjust focus.

-

Hit start — engraving is usually complete in minutes.

-

Minimal post-processing required.

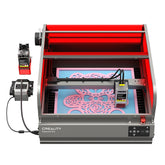

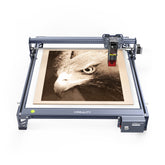

👉 Devices like the Falcon A1 Pro 20W Dual-laser Engraver even feature autofocus and app monitoring, making them user-friendly.

CNC Router Workflow

-

Create or import design in CAD software.

-

Generate toolpaths in CAM software.

-

Secure material, select the right bit, set spindle speed and feeds.

-

Cut the project — which may take hours.

-

Post-process (sanding, assembly, finishing).

CNC routers require more preparation and technical understanding, making the learning curve steeper.

Cost and Maintenance Considerations

Laser Engravers

-

Entry-level: ~$700–$1500 (diode).

-

Mid-level: ~$2000–$4000 (CO₂).

-

Maintenance: Low (clean lenses, air assist, filters).

-

Running cost: Minimal, aside from electricity.

CNC Routers

-

Entry-level hobby routers: ~$1500–$3000.

-

Professional shop routers: $5000+.

-

Maintenance: Tool bits wear down and need replacing.

-

Running cost: Higher (bits, dust collection, lubrication).

For most small creative businesses, laser engravers often deliver a faster ROI because of the popularity of personalized products.

Design and Software Requirements

-

Laser engravers: Work well with LightBurn, Illustrator, CorelDRAW. Setup is simple, and many machines include camera systems for positioning.

-

CNC routers: Require CAD/CAM knowledge (Fusion 360, VCarve, AutoCAD). More powerful, but less beginner-friendly.

If you’re already skilled in CAD modeling, CNC routers may feel natural. If not, laser engravers offer a smoother entry point.

Practical Examples

-

A crafts business engraving cutting boards, mugs, or jewelry: Laser engraver is the clear choice.

-

A woodshop building custom cabinets: CNC router is better.

-

A sign-making shop: Both — router for large structures, laser for fine text and logos.

-

A STEM classroom: Laser engravers are safer and easier for students to learn.

Safety and Workspace Requirements

-

Laser engravers: Safer in enclosed designs, need smoke extraction. Quiet compared to routers.

-

CNC routers: Loud, dusty, require dust collectors and ear protection. Better for dedicated workshops.

For home and educational spaces, laser engravers are usually more practical.

Using Both in One Workshop

Many makers find the ideal solution is not choosing, but combining:

-

CNC router for large wooden frames.

-

Laser engraver for fine engraving and detail.

-

Hybrid workflow that produces both structure and artistry.

👉 For example, a furniture shop could cut wooden panels on a CNC router, then personalize them with a laser engraver like the Falcon2 Pro 40W Enclosed Laser Engraver.

Future Outlook: The Evolving Maker Toolkit

-

Laser engravers: Getting smarter with autofocus, flame detection, and mobile app control.

-

CNC routers: Moving toward automation with tool changers and hybrid systems.

The future isn’t about one replacing the other, but using each where it excels.

Conclusion: Which One Is Right for You?

-

Choose a laser engraver if your focus is personalization, crafts, and fast precision work.

-

Choose a CNC router if your focus is structural, large-scale, or heavy-duty fabrication.

-

Choose both if you want to build a versatile workshop that handles everything from cabinetry to custom jewelry.

👉 Ready to explore? Discover the Creality Falcon collection and see how machines like the Falcon A1 Pro 20W and Falcon2 Pro 40W can transform your creative workflow.